Australia Exports Carbon Fibre Furnaces

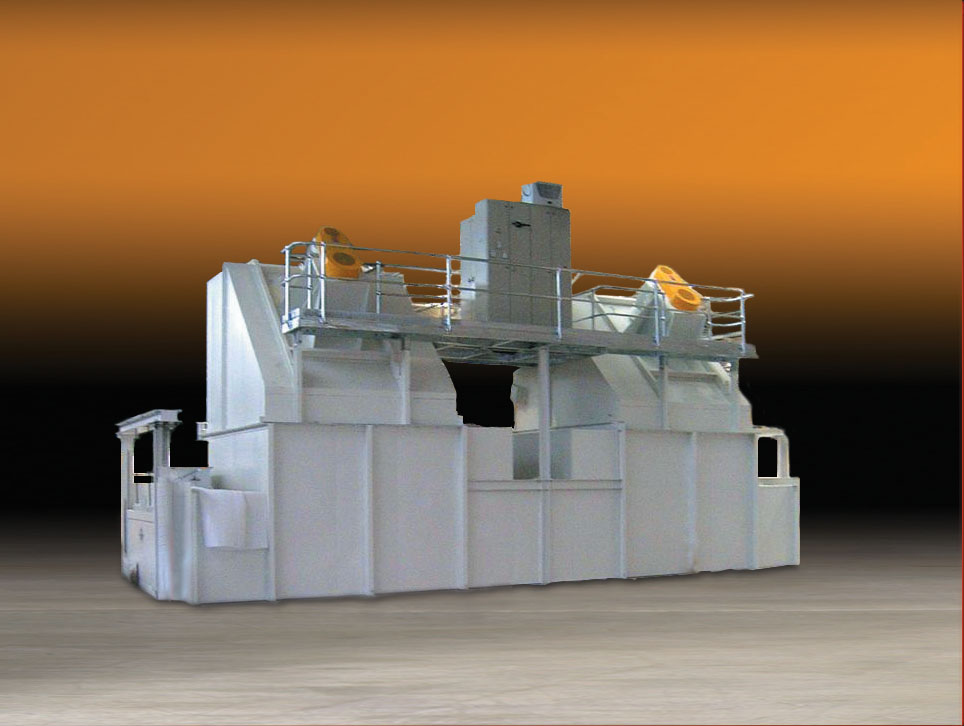

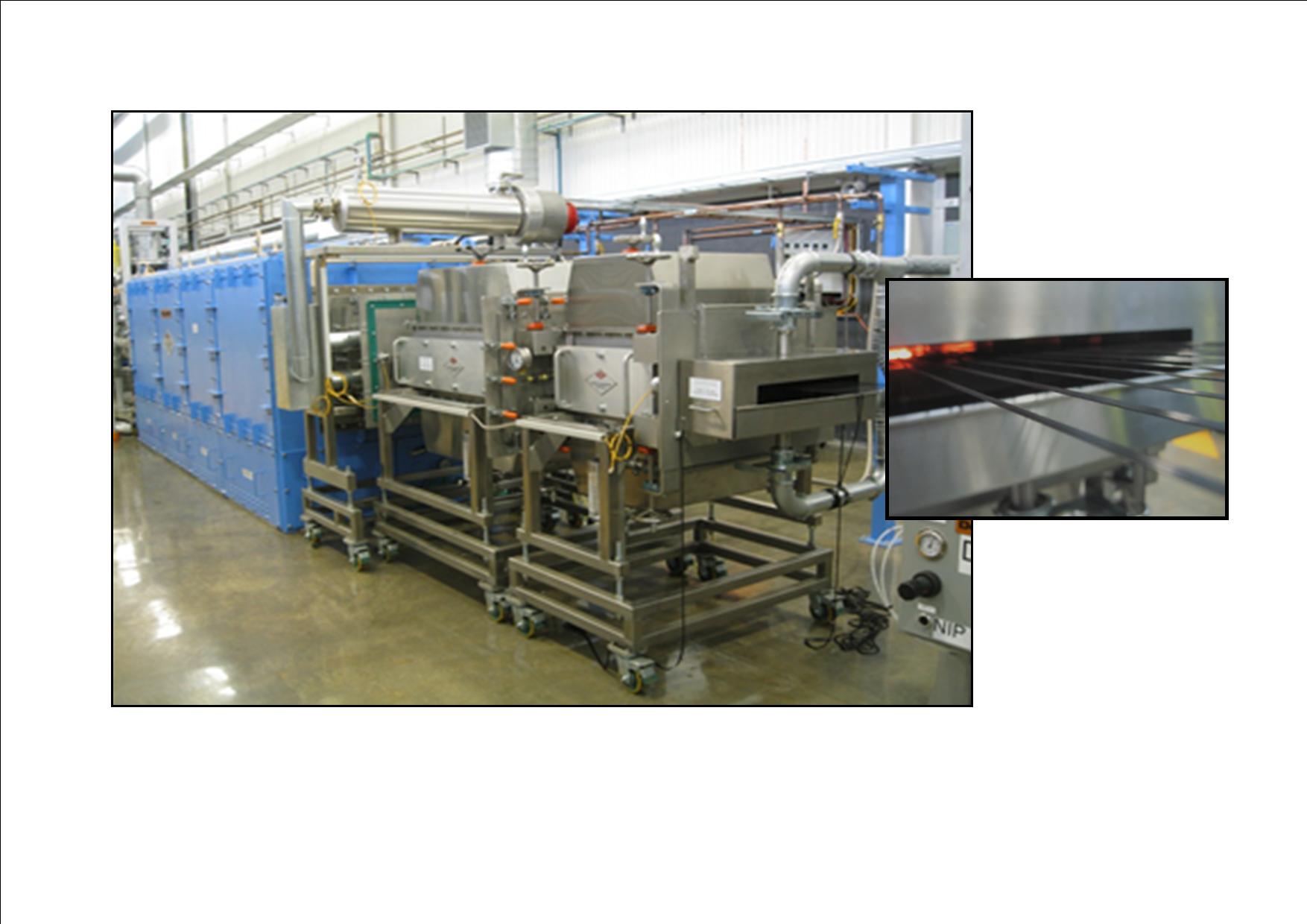

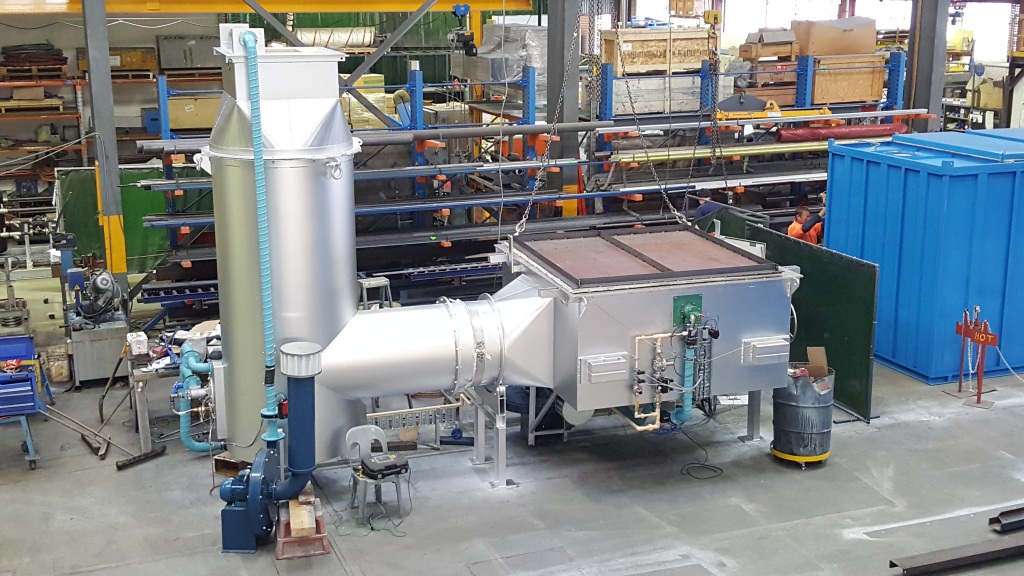

Furnace Engineering has completed and tested two Australian designed and built carbonisation furnaces ready for export to a Europe based client. These furnaces were selected in preference to products from other international competitors. The client’s decision was based on the excellent results that have been achieved with similar furnaces designed and made by Furnace Engineering operating at the Carbon Nexus facility based at Deakin University in Geelong. The client conducted stringent pre delivery acceptance tests at Furnace’s Notting Hill facility, taking the furnaces to the conditions required for the carbonisation of oxidised polyacrylicnitrile (PAN) fibres as used in carbon fibre manufacture.

The furnaces replicate, as far as possible, typical full scale production equipment according to principal designer and one of the directors at Furnace Engineering, Brian Gooden. The sale is a good example of how industry and the research community can both benefit by working together. Clients can gain expertise, familiarity and confidence with the equipment at Carbon Nexus prior to purchase and the equipment designer learns what the researchers really need.

We have more ideas in the pipeline explains Gooden. Our traditional heat processing clients in the manufacturing sector may have declined, but we find an increasing number of clients seek us out to solve challenging new heat proceeding problems across a very wide range of applications.

latest news

ICCM22 International Composite Material Conference

Back in Australia for the first time since 1997, the biennial International Conference on Composite Materials brings together 1500 professionals from ...

Curing Oven - Double Lift Door Design

The Furnace Engineering designed curing ovens offers enhanced temperature uniformity and shorter cycle times when curing parts. The ovens are man...

Fire Testing of Metro Tunnel Components

The following link - to Network 7 National News - illustrates our expertise in Fire Testing. Not only the furnace itself: the critical blend of ...

Infra-red heating is extremely useful for fast-response heating. Whilst many of our infra-red heaters use electrically heated quartz-tube emitters, th...

Furnace equipment is rarely “off the shelf”, and this one is no exception. The equipment is custom-designed for the application. Thi...

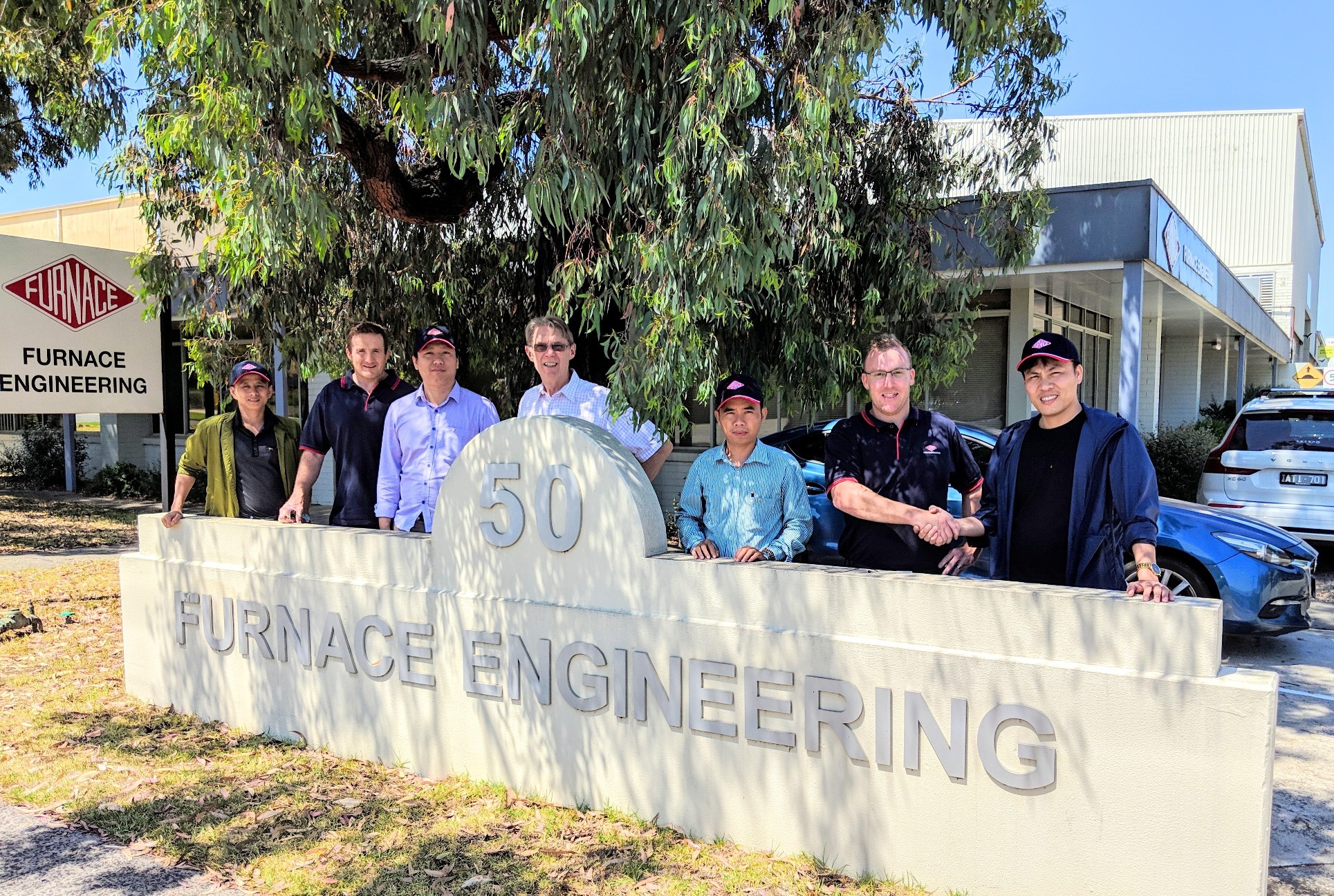

Last week we hosted a team of visitors from Vietnam to inspect a large process heater to be installed in a fertiliser plant in Vietnam. The sign...

Clean Process Ovens are vital for advanced manufacturing in the medical technology space, and Furnace Engineering is proud to partner with customers i...

Go Carbon 2018 in Berlin was a great opportunity for the carbon fibre industry to gather and learn. Brian Gooden delivered a paper on our Carbon...

Clean Process Ovens are vital for advanced manufacturing in the medical technology space, and Furnace Engineering is proud to partner with customers i...

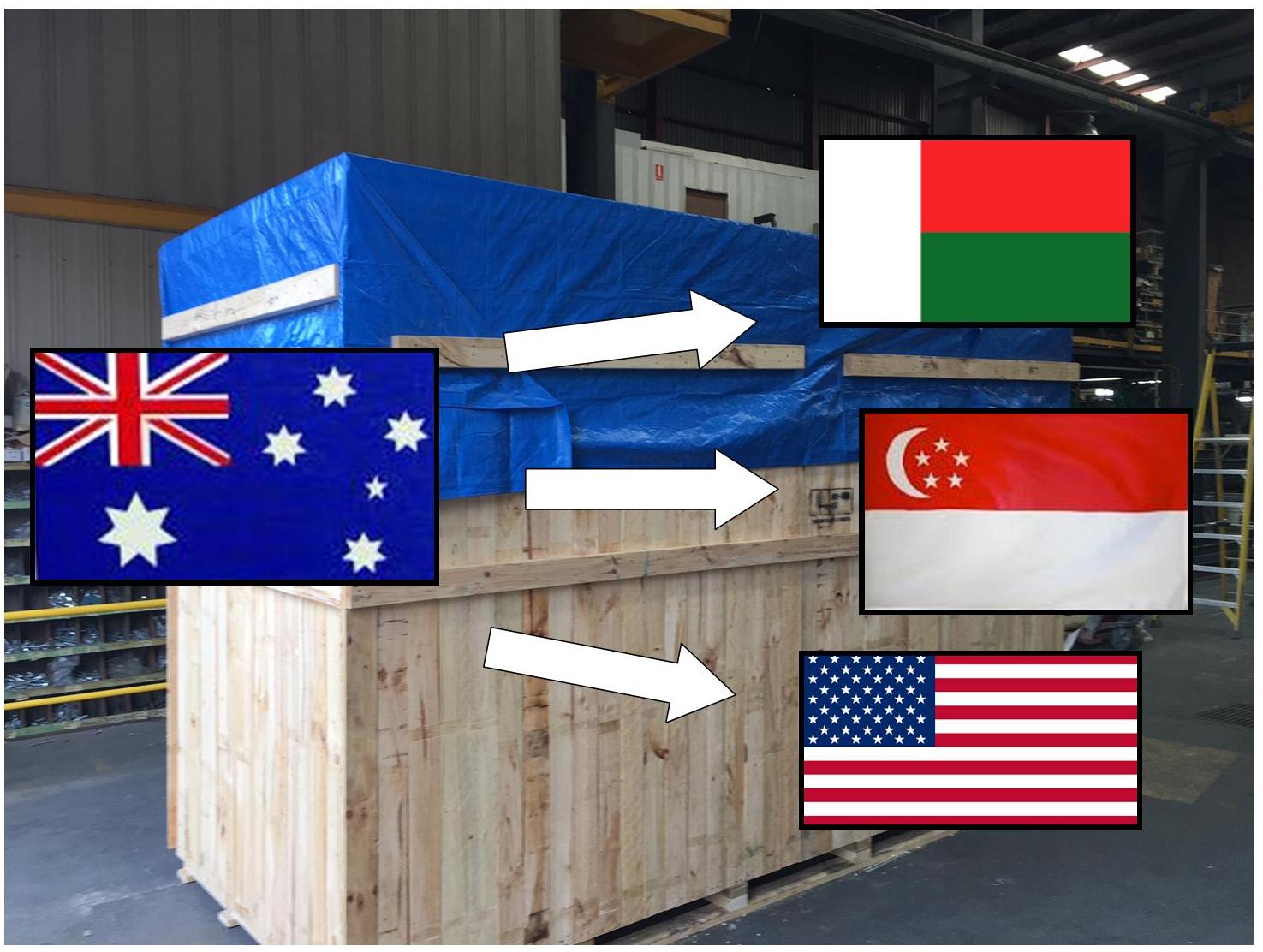

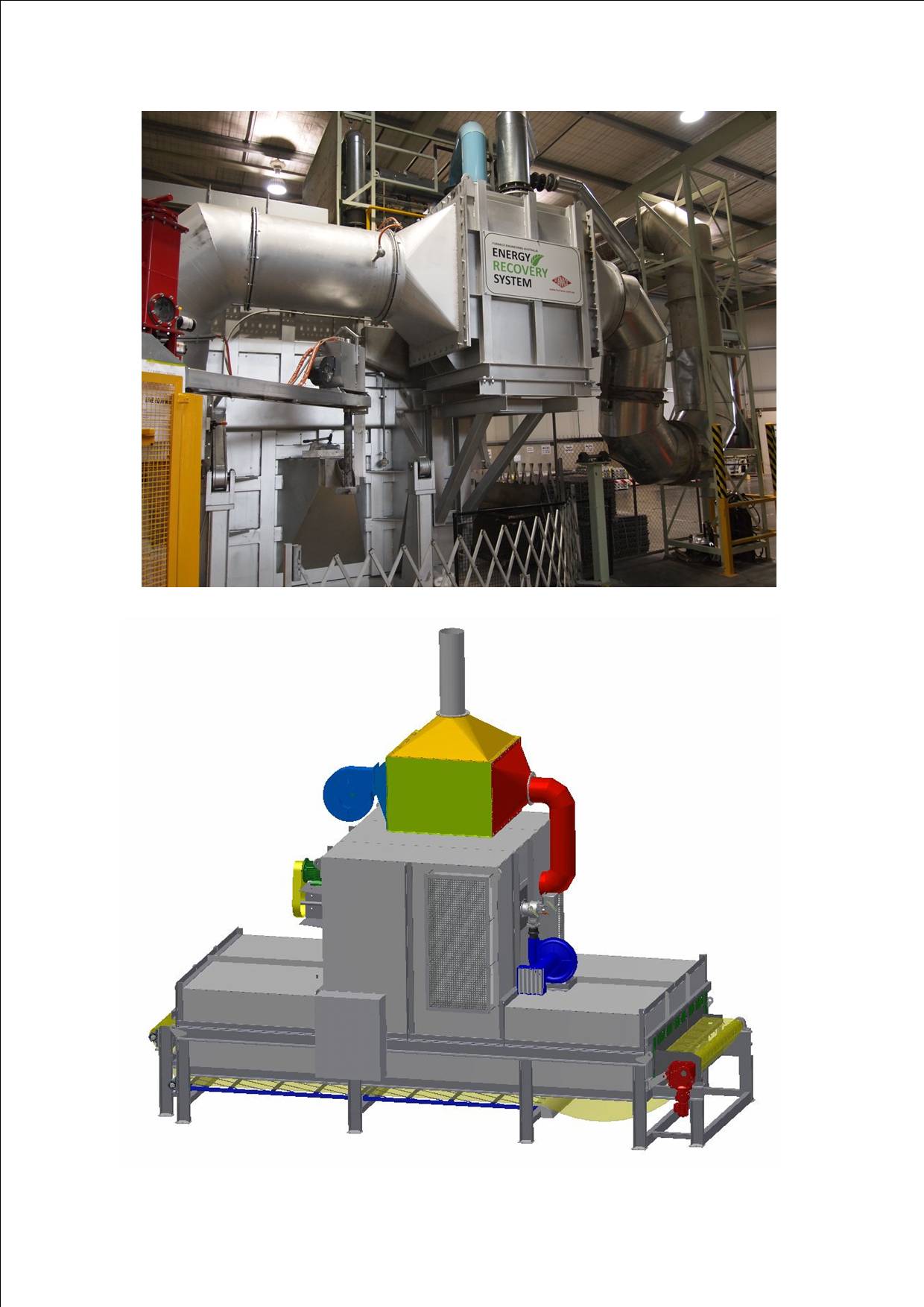

Another proud Export moment for Furnace Engineering - shipping our first complete “Carbon Fibre Hot Package” for conversion of PAN to Carb...

Furnace Engineering has a long tradition of training staff via apprenticeships. Training our own staff gives us the chance to impart those skill...

This picture captures the decisive moment - firing of the glass furnace for the first time after a thorough refurbishment and rebuild campaign.&n...

High value parts deserve to be treated well. This furnace combines individual part processing, atmosphere control plus automation and traceabili...

We often encounter production processes that have “always been done that way”. No one is sure of what effect the variables such as a faste...

Aluminium heat treating requires precision - this recently-completed drop-quench furnace performs solution heat treatment of aluminiu...

2017 Christmas Holiday Shut-down

Our office will be shut from Friday 22 December 2017 and re-opening on Monday 8 January 2018. There will be a skeleton staff operating throughout t...

Some of Furnace Engineering’s “simple” heating applications are deceptively complex. These drum heating ovens are designed and...

Our top-loading heat treatment furnaces are designed for easy top-loading by overhead crane, with a typical load being large forged and welded steel c...

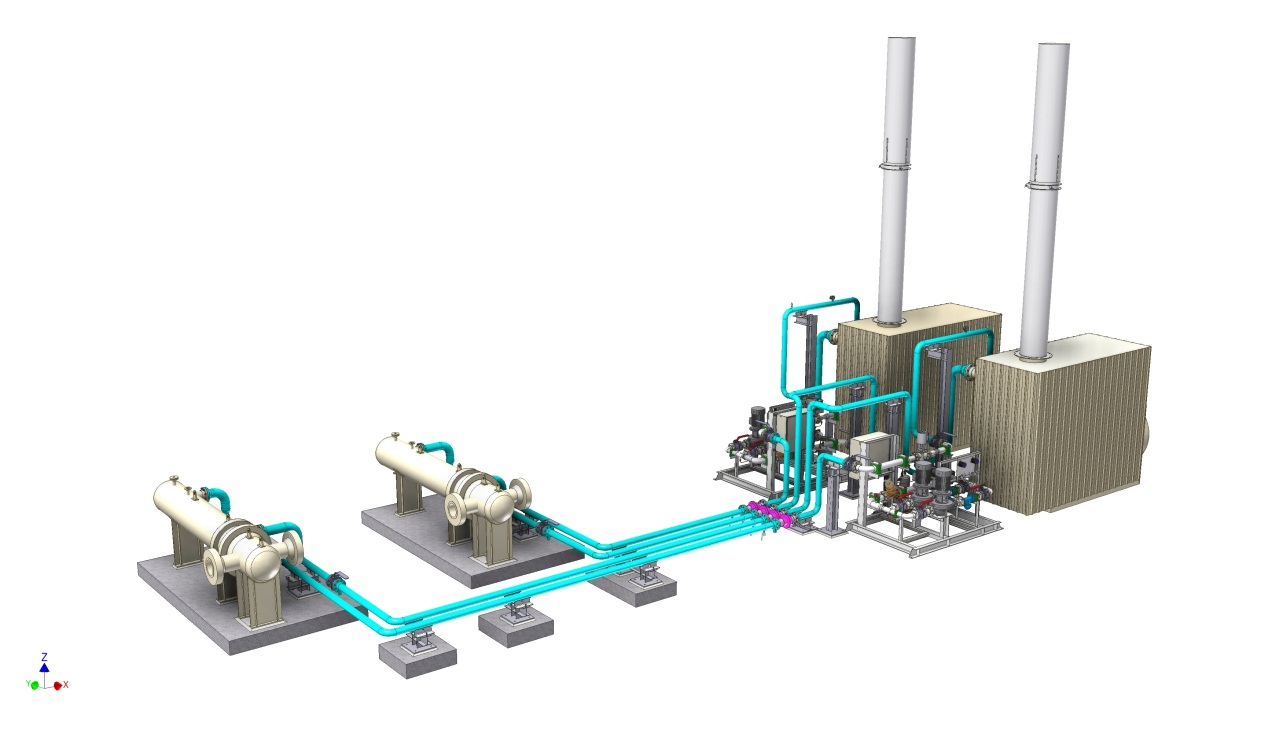

The FEGAS commissioning team took these images at the natural gas heating stations supplied recently to Young, NSW. This project will allow...

Induction Heating Applications for Industry

Induction heating is an efficient, fast and cost-effective way of heating metal parts. Furnace Engineering designs bespoke heating systems for a...

Furnace Engineering has been awarded a patent for its novel Atmosphere Curtain and Cooler. This design was used in the Carbon Fibre carbonisation furn...

Furnace Engineering has commenced combustion system engineering of a large glass furnace upgrade for a leading glass producer. Upgrade work takes plac...

LeMond Composites has partnered with Deakin University to commercialise Deakin’s patented low-cost carbon fibre technology. This revolutio...

With soaring gas and electricity prices and, operating efficiency and heat recovery have become an essential part of the design of modern industrial f...

Just delivered, a continuous mesh belt heat treatment furnace, custom designed and built for a customer who is engaged in support activity to Australi...

Massive Heat Treatment Furnace

Furnace Engineering is called upon to design and build some extremely large furnaces, and this furnace is almost certainly the larges...

National Manufacturing Week - Melbourne

National Manufacturing Week | 9 - 12 May 2017 | Melbourne Convention & Exhibition Centre This is a free event, bringing you the best...

Aerial Footage of Gas Heating System

A recent gas heating system was photographed by Drone video camera. Unique images of the equipment during factory acceptance testing. The ...

Furnace Engineering recently completed a Researcher-In-Business program in conjunction with Swinburne University. The goal of the program was to...

This large Fire Test Furnace will perform tests to establish the fire resistance of materials of construction, in compliance with international codes ...

Furnace Engineering is proud to announce its appointment as official representative of UBE Machinery Corp of Japan, for Australia and New Zealand...

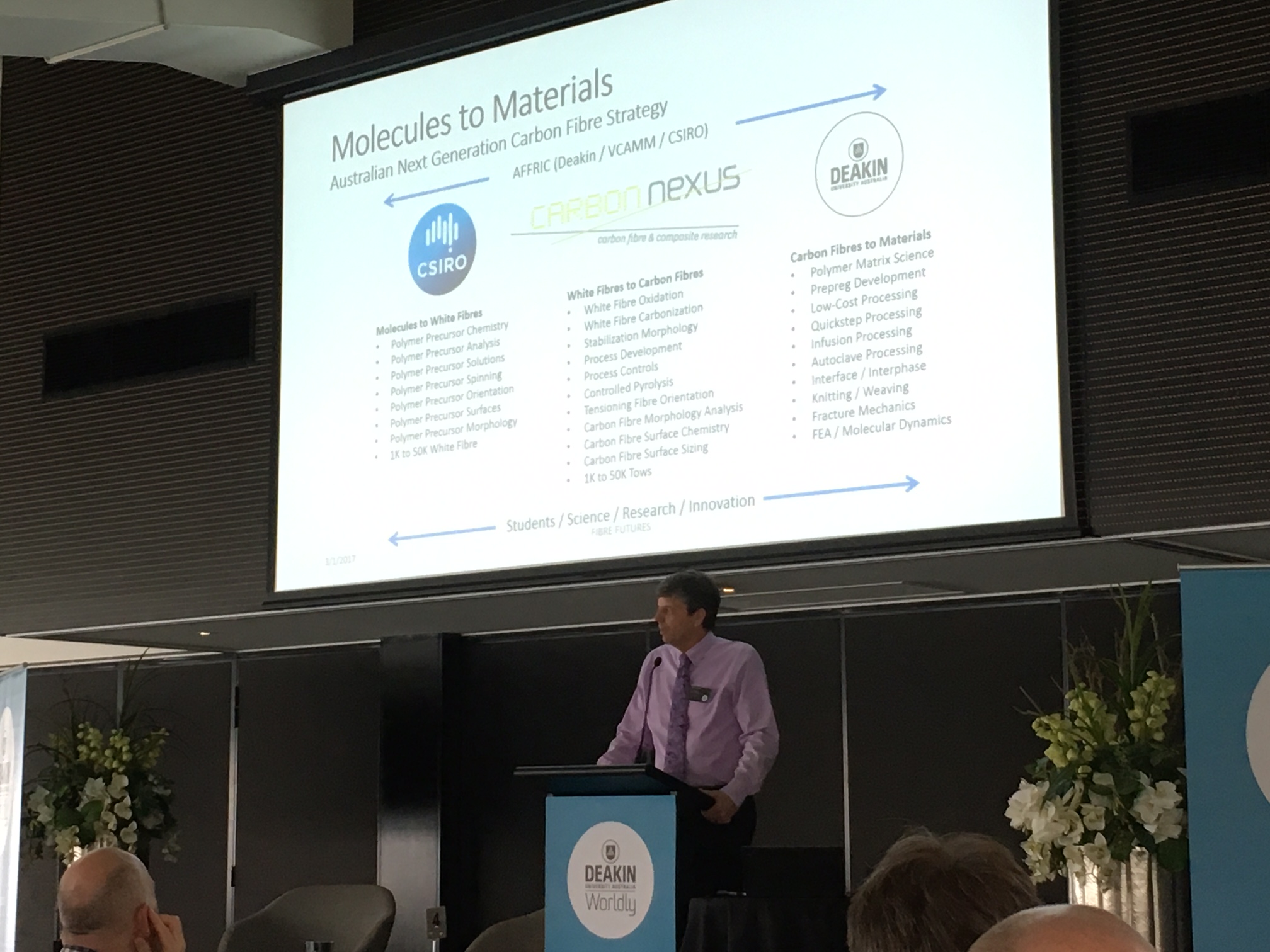

Furnace Engineering once again are proud participants and sponsors of the Carbon Fibre Futures Conference, 1-3 March 2017. http://www.carbonfibr...

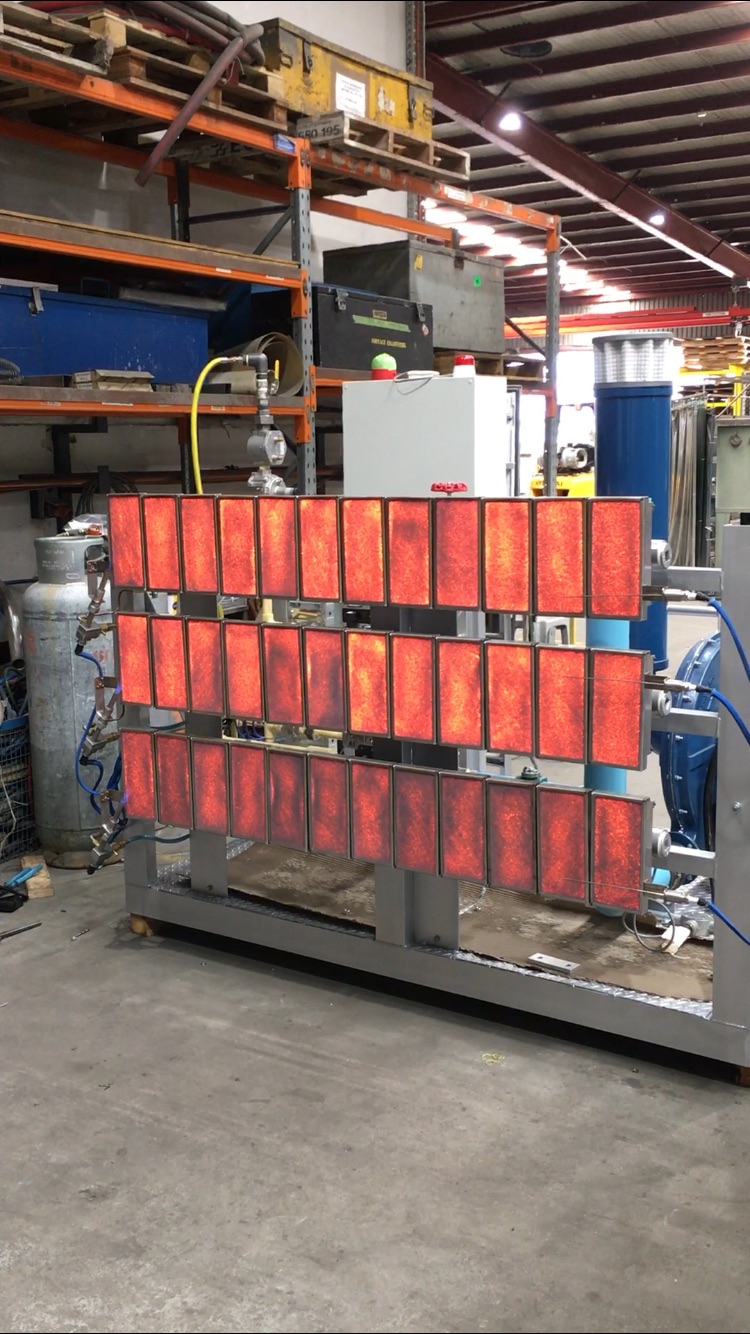

The picture illustrates one of our latest combustion systems. This is a 12 burner firing system for a large research furnace, with an overall fi...

The FEGAS team, pictured, are celebrating FAT (sign-off) of a the gas pressure reduction system for instalation in Young, NSW. The project w...

Espec Climate Simulation Chambers

Furnace Engineering supplies Espec Climatic Simulation Chambers for Australia and New Zealand. Recent installations include a chamber which was ...

Wesmartin, a division of Furnace Engineering , designs and produces Clean Process and Food Production equipment. The curing oven shown here oper...

Furnace Engineering often handles projects with unusual, specific and often technically challenging requirements. These furnaces were custom-des...

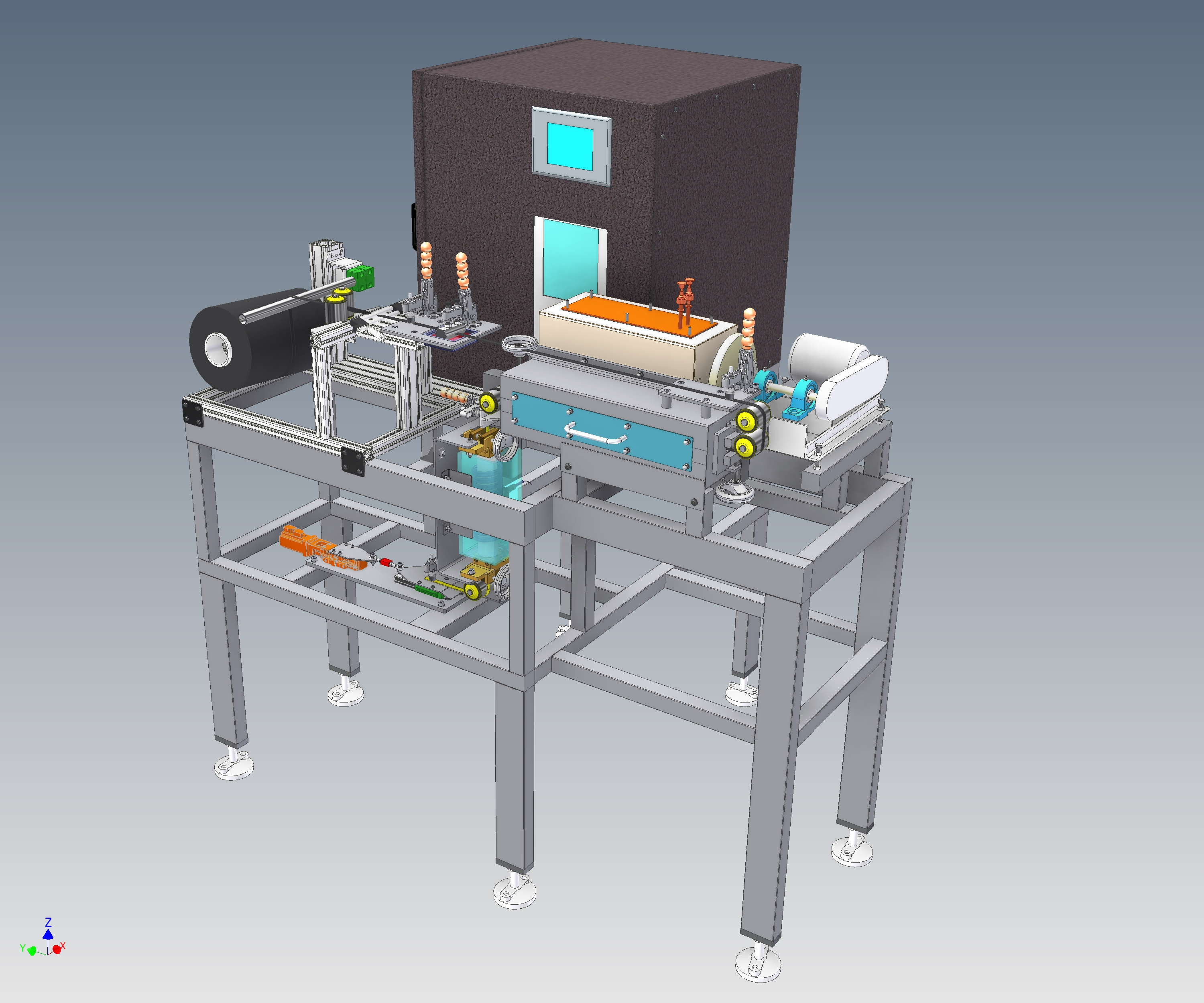

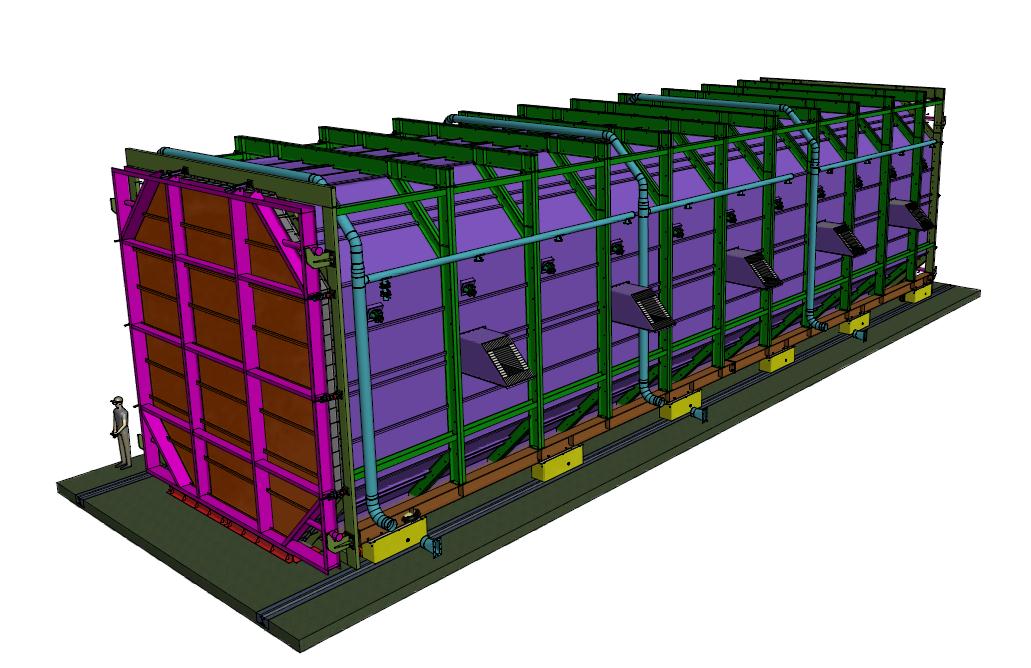

Carbon Fibre Production Simulator

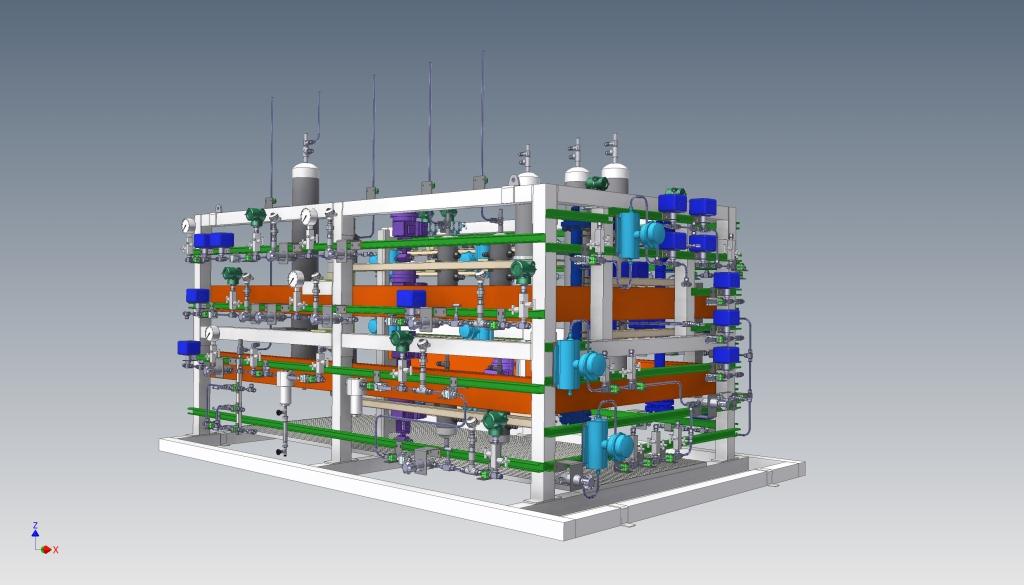

Furnace Engineering has designed and built a Carbon Fibre Production Simulator (CFPS) to complement its range of heat processing equipment for the Car...

Furnace Engineering is proud to announce that final stages of internal testing are under way in our factory for our CO2 separation research system. ...

Furnace Engineering has just delivered a rotating furnace to perform fire testing on construction and building materials. The furnace is complete with...

Installation of Continuous Enamelling Furnace

Furnace Engineering has been awarded a contract to design, supply and install a continuous enamelling furnace. The furnace is 20 meters long, 5 meters...

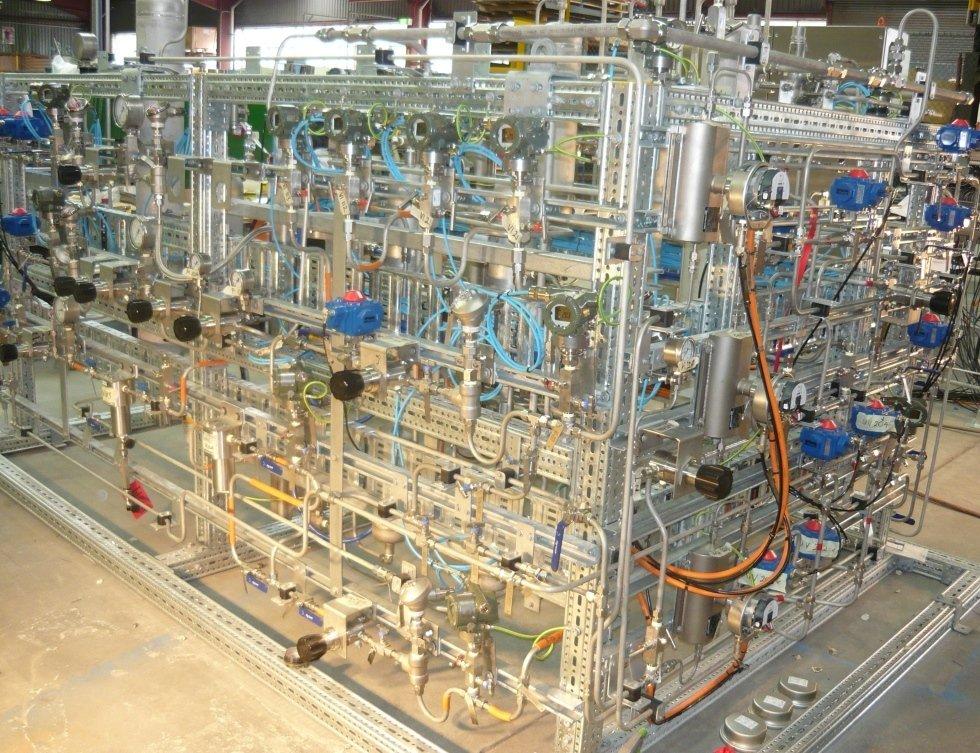

FEGAS (Furnace Engineering Gas Division) has been awarded a contract to design and supply a CO2 separation rig by one of the major research organizati...

Young Pressure Reducing Station Project

FEGAS has been awarded the contract to design, manufacture and supply the heating system for the new Young PRS. This project will allow injection o...

Victoria University - Fire Test Furnace

Furnace Engineering has recently been awarded the contract to supply a 4m x3 m integrated fire testing furnace for Victoria University. This furnace w...

Bendigo & Ballarat Natural Gas Heating Packages

With the successful completion of commissioning and Site Acceptance for Ausnet Service’s Bendigo PRS, it brings to a close a contract with Tenix...

Furnace Engineering was among a group of companies recognised for their contribution to Aviation Aerospace Australia at their annual award ceremo...

Furnace Engineering completed the design of a stress relieving furnace and the construction is on-going at Thornton Engineering’s stat...

Thermal processing for the Aerospace Industry

Furnace Engineering contributed to the development of the Course in Pyrometric Requirements for Thermal Processing for the aerospace maintenance...

National Manufacturing Week 2015

Check out our presentation here: Furnace Engineering National Manufacturing week Thank you for visiting the Furnace Engineering Stand 4803 at the N...

Furnace Engineering awarded VEEA

Furnace Engineering awarded in Engineers Australia’s 2014 Victorian Engineering Excellence Awards. Furnaces for the production of Carbon Fibr...

Austrade Trade Mission to Singapore August 2014

Furnace Engineering, represented by Brian Gooden, participated with other Australian Based Aerospace Industry suppliers in an Aerospace Business Missi...

Deakin University $34m Carbon Fibre Facility

Australia now has a state of the art Carbon Fibre Research facility installed at the Carbon Nexus site at Deakin University in Geelong, Australia...

Carbon fibre production heats up

Furnace Engineering is supporting Australia’s entry into the production of carbon fibre with the design and supply of furnaces. It has d...

Fyshwick Trunk Receiving station upgrade is one of the major gas projects in ACT region, to secure gas supply in one of the fastest growing market in ...